About the International PV Quality Assurance Task Force

The International Photovoltaic Quality Assurance Task Force (PVQAT) leads global efforts to craft quality and reliability standards for solar energy technologies. These standards will allow stakeholders to quickly assess a solar photovoltaic (PV) module's performance and ability to withstand local weather stresses, thereby reducing risk and adding confidence for those developing products, designing incentive programs, and determining private investments.

As a result:

- Investors can gain confidence in solar investments

- PV customers can use standards to choose products that meet their needs

- Incentive programs can define a minimum durability for module designs

- Insurance companies can adjust rates according to demonstrated reliability

- PV module suppliers can optimize module design to minimize cost while still maintaining confidence in reliability for a specific use or application of the modules

- The entire PV community benefits by reducing installed PV cost.

Approach

PVQAT strives to provide these benefits by coordinating international development of comprehensive technical standards for verifying PV component and system quality and bankability. To that end, PVQAT has a three-pronged approach that seeks to establish:

- Tests and ratings to ensure durable design of PV modules for climates and applications of interest

- Guidelines for factory inspections and quality assurance (QA) during manufacturing

- A comprehensive system for certification of PV systems, verifying appropriate design, installation, and operation.

PVQAT has several individual task groups focused on accelerating progress toward implementing these three approaches. As today’s products and industry needs are evolving, our task groups do, too. Task groups may form on a new subject, become idle on an older subject, or re-activate when needs for a new test or standard surface. Contact us if you would like to start a new task group or sub-group effort.

History

The idea for an international photovoltaics quality assurance task for began in 2010. Japan wanted to ensure success of their second incentive program for solar systems. The Ministry of Economy, Trade and Industry in Japan asked the United States Department of Energy to join in leading an international effort on quality and reliability of photovoltaics.

The first International PV Module Quality Assurance Forum was held in July 2011 in San Francisco, California. The event fostered international participation to develop a rating system that meets the needs of all countries and customers, so PV manufacturers need to complete only a single test. At the forum, the community expressed strong support for development of international PV QA standards, leading to the formation of PVQAT.

International Photovoltaic Standards Development

The International Electrotechnical Commission (IEC) has set a minimum design criterion for PV qualification test standards. While beneficial to the PV community in many ways, IEC 61215, IEC 61730, and IEC 62108 do not attempt to give confidence for decades of solar energy system use and do not provide a mechanism to adjust requirements based on regional differences in PV module stresses.

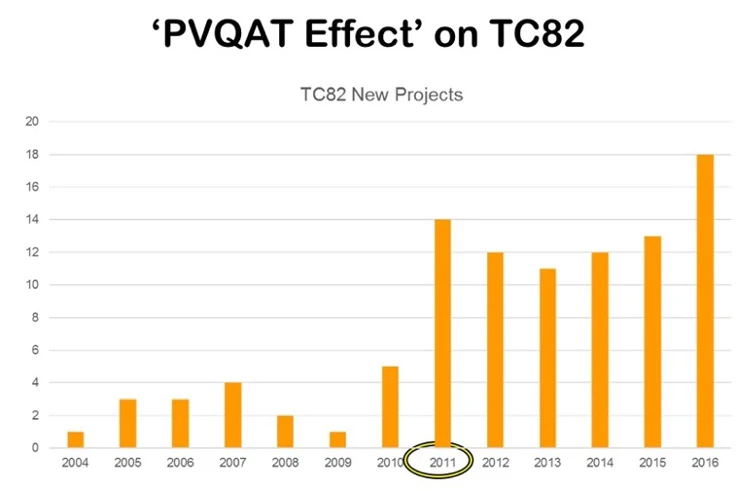

The initiation of PVQAT resulted in a remarkable burst in standards activity. The IEC Technical Committee 82 Secretary’s Report in 2017 called this the ‘PVQAT Effect’ on TC82.

Therefore, PVQAT seeks to develop the science and testing procedures that enable more beneficial standards. Such standards may relate to new technologies (such as new polymers or cell types, new uses conditions (such as higher system voltage or temperature), and longer-term assessments of module durability.

In general, QA covers safety and environmental issues as well as product performance. These issues may interact with one another in many cases. However, PVQAT focuses primarily on performance aspects and looks specifically at two key parts of QA:

- The original design to ensure the desired reliability

- The manufacturing process to ensure consistent quality.

Customer confidence in PV module QA will be improved by international standards that more consistently oversee the QA programs in place at each factory. This type of QA standard is implemented by IEC and IECRE.

Meaningful service life prediction must be done as part of a quality management system to provide information about a product with a specific bill of materials, manufactured within a specified process window for a defined application. Such quantitative prediction is the end goal.

Get Involved

PVQAT encourages participation by all types of stakeholders, including PV customers, incentive programs, investors, insurance companies, PV manufacturers, PV test labs, and PV standards organizations. Stakeholders bringing a new examination to the task force are welcome to form a new task group or subgroup. Please contact us or subscribe for email updates for further information.